- Nielsen Enterprises

- Software

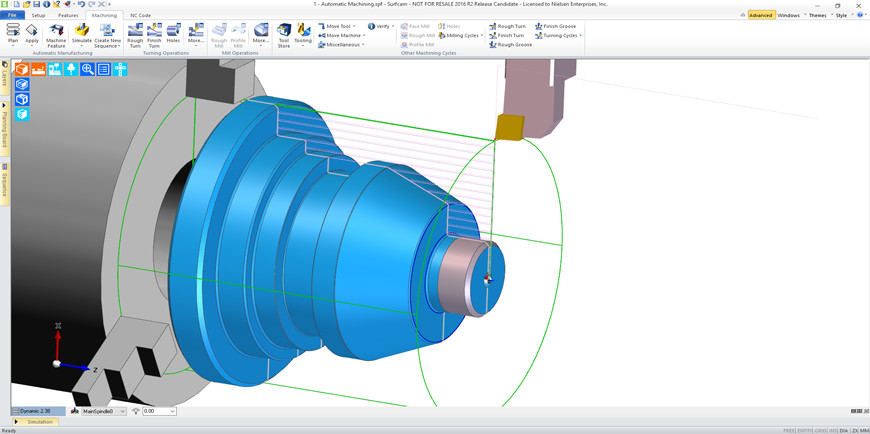

- Surfcam Turning

Essential Turning Overview

2 Axis Turning - Product Code: SE302-0

Facing

Facing operations provide for the stock end cleanup as well as part finishing. Front and Back face machining operations are available within Essential Turning as well as support for face features such as grooves and bores.

Rough/Finish Turning

SURFCAM provides a series of basic lathe cycles within Z and X axes. They move together with a rotating spindle and machine a part on the spindle. Toolpaths can be stock aware and can have variable stock to leave on each axis.

Threading

Multi-pass threading cuts can be applied to turned parts. Threading cycles are both depth and material aware so as to not overload the tool.

Rough/Finish Grooving

Rough and Finish grooving operations are provided supporting both shallow and deep operations and a wide variety of tools.

Hole Cycles

SURFCAM supports drilling and boring as turn operations at the Essential level. For drilling operations the tool can be in either a fixed or live state.

Standard Turning Overview

2 Axis Turning with C/Y Axis Milling - Product Code: SE20C-0

C/Y Axis Milling – 3D Roughing for Wireframe

3D rough milling operations can be applied to both 2D wireframe sections and 3D wireframe geometrical features.

C/Y Axis Milling – 3D Roughing for Surfaces and Solids with Automatic Rest Roughing

3D rough milling operations can be applied to both surfaces and solids. When using surfaces or solids the geometry is stock aware and automatic rest roughing is available.

C/Y Axis Milling – Trochoidal Milling Option

This is a high speed roughing method. A full width cut move exceeds the specified stepover, potentially overloading the tool. Using the trochoidal roughing reduces the load on the tool to a more consistent level with inserting the arc move. It achieves an extended tool life while allowing higher machining speeds to be maintained. In a narrow channel or tight corner, there may not be room for a trochoidal cut, in this case the area is excluded from the cycle. In the most of the cases, the Waveform Roughing shows better results as this uses the most advanced technologies.

C/Y Axis Milling – 3D Profile Finishing with Cusp Height and Helical Milling Options

3D profile finishing operations include cusp height calculations at this product level along with the more traditional percentage stepover moves.

C/Y Axis Milling – Flatland Finishing and Flatland Rest Finishing

Automated flatland recognition allows for selection of appropriate tools, feeds and speeds for clean flat finishing. Optimized finishing and rest finishing operations are included.

Advanced Turning Overview

Multi-Axis Turning for Mill-Turn Applications - Product Code: SE4CY-X

B, C, and Y-Axis Milling Capabilities

All milling functions are operational within the B, C and Y axis of the machine tool while the spindle is in a fixed plane position.

Multi-Axis Turning for Mill/ Turn Applications

All milling functions are operational on the milling axis of the machine tool while the spindle is in live operation providing an additional cutting axis.

Sub-Spindle Part Transfer

Part transfer operation from the primary to the secondary sub spindle is supported for both the machining and simulation environments.

Lathe Index

Lathe operations are capable of orienting the milling axis to the machining plane and perform 2-Axis to 3-Axis Milling.

Bar Pull

Bar pull operations are supported for lathers with stock feed.

Synchronized 4 Axis Rough Turning / Facing

Rough turning and facing using 2-turret at the same time in the turning environment. The basic turning (lathe) is 2-Axis (ZX). Using the 2-turret, the number of the active axes on a spindle will be double.

Support for Single Spindle, Single B-Axis Head Machine Configuration

The addition of a B-axis head machine configuration is supported.

Ultimate Turning Overview

Multi-Axis Turning for Mill-Turn Applications - Product Code: SE4BC-X

B,C/Y Axis Milling – 3D Roughing with Automatic Rest Roughing

3D roughing with automatic rest roughing is supported for both the B axis milling head and the C/Y Axis.

B,C/Y Axis Milling – Adaptive Feedrates

Adaptive Feedrates are supported for both the B axis milling head and the C/Y Axis.

B,C/Y Axis Milling – Trochoidal Milling Option

The Trochoidal Milling option is supported for both the B axis milling head and the C/Y Axis.

B,C/Y Axis Milling – 3D Profile Finishing with Cusp Height, Check Surface and Helical Milling Options

3D profile finishing, including stepover based finishing and cusp controlled operations are supported for both the B axis milling head and the C/Y Axis. This includes the use of Check surfaces for gouge control and helical milling options.

B,C/Y Axis Milling – Flatland Finishing and Flatland Rest Finishing

Automated flatland recognition allows for selection of appropriate tools, feeds and speeds for clean flat finishing. Optimized finishing and rest finishing operations are supported for both the B axis milling head and the C/Y Axis.

B,C/Y Axis Milling -Parallel Lace with Up/Down Control

Parallel lace machining with up/down control is supported for both the B axis milling head and the C/Y Axis.

B,C/Y Axis Milling – Finish Shallow Areas

Shallow area finishing is supported for both the B axis milling head and the C/Y Axis.

B,C/Y Axis Milling – Steep Shallow Rest Finishing

Steep Shallow rest finishing is supported for both the B axis milling head and the C/Y Axis.

B,C/Y Axis Milling – Constant Cusp Finishing

Constant cusp finishing is supported for both the B axis milling head and the C/Y Axis.

B,C/Y Axis Milling – Contact Angle Control

Contact angle control is supported for both the B axis milling head and the C/Y Axis.

B,C/Y Axis Milling – Multi Tool Rest Finishing

Multiple tool rest finishing is supported for both the B axis milling head and the C/Y Axis.

Pencil Milling

Pencil Milling is supported for both the B axis milling head and the C/Y Axis.

Check Surface Control

Check surface control is supported for both the B axis milling head and the C/Y Axis.